EPSILON BURS

EPSILON BURS

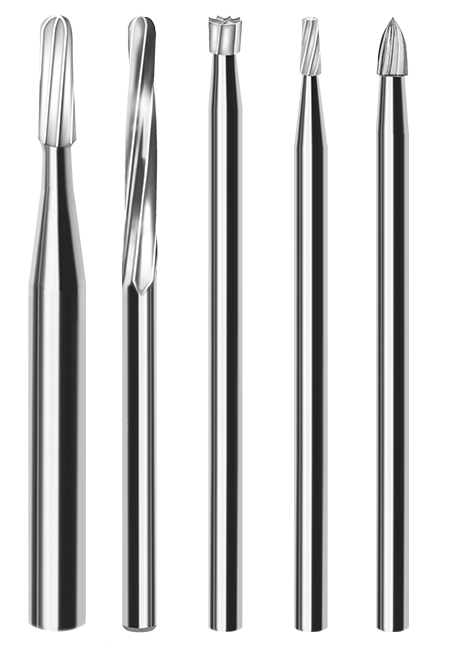

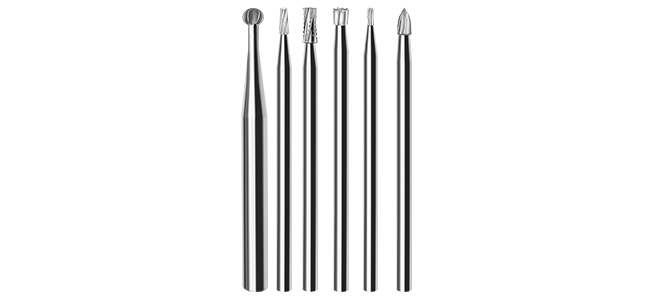

Introducing our remarkable Epsilon Burs, crafted with customized grade of tungsten carbide that are best suited for dental procedures, ensuring exceptional performance and longevity. The sharp rake angles of our Epsilon carbide burs enable swift, accurate, and efficient cuts through ceramic surfaces.

Features

Accurate cuts

Smooth cuts

Longevity

Fast cuts

01. EPSILON BUR CATEGORIES

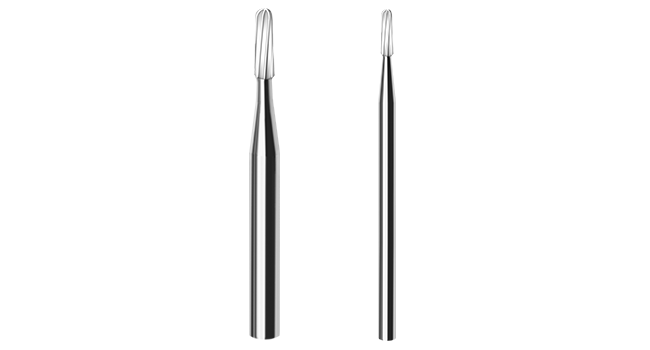

Epsilon metal ceramic cutting bur, manufactured from a robust grade of carbide to facilitate effortless and rapid cutting of metal ceramic crowns. Designed with convenience in mind, these burs are also available in a long shank variant. With a high degree of concentricity, they ensure precise and accurate performance, while their exceptional durability and stability aids in long-lasting usability.

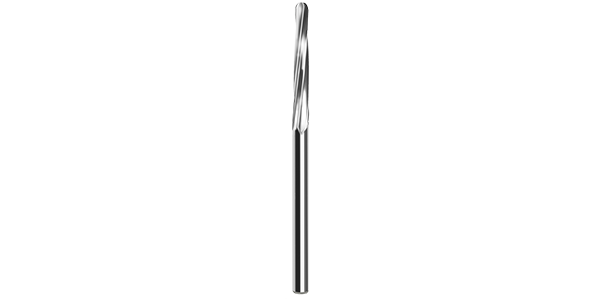

Our Epsilon taper fissure surgical length bur, specifically designed with special grade of carbide for optimal performance during extraction procedures. These burs facilitate quick and precise cross-sectioning of impacted molars in a matter of seconds. Experience the smooth operation without any chatter or vibrations, ensuring a comfortable and efficient extraction process.

HP burs, specifically designed for use with straight handpieces. These burs are made with specialized grades of tungsten carbide. The wide range made by Piscium are perfectly suited for various dental procedures.

Read precautions carefully

- The device is to be used on the instruction of and by a registered dental practitioner

- Always use sterilized forceps and fresh gloves when handling dental burs

- Eye protection must be worn to protect against ejected particles

- Burs must be sterilized before first use and before every use thereof

- Surgical masks must be worn to avoid inhalation of aerosol or dust generated

- Ensure that the bur is securely gripped in the handpiece collet

- Do not use worn-out burs

- Maintain handpieces in good working order and correctly lubricated

- Do not exceed the maximum speeds tabulated in the product leaflet

- Do not apply excessive pressure or shear on the bur

- Avoid removing the bur at too sharp an angle to avoid leverage and breakage

- Move the bur continuously when in use to avoid localized heating and/or damage to the bur

- Read carefully the labels on the packaging

- Do not touch the bur when in motion

- Remove the bur only after it has come to a complete standstill

- This bur should be used on hard dental tissue only

Guidance for maximum RPM

| Instrument head diameter (1/10 mm) | Maximum permissible speed (RPM) | Recommended operational speed (RPM) |

|---|---|---|

| 007 - 010 | 450,000 | 100,000 - 220,000 |

| 011 - 014 | 450,000 | 70,000 - 220,000 |

| 015 - 018 | 450,000 | 55,000 - 160,000 |

| 019 - 023 | 300,000 | 40,000 - 120,000 |

| 024- 027 | 160,000 | 35,000 - 110,000 |

| 028 - 031 | 140,000 | 30,000 - 95,000 |

| 032 - 040 | 120,000 | 25,000 - 75,000 |

| 041 - 054 | 95,000 | 15,000 - 60,000 |

| 055 | 60,000 | 12,000 - 40,000 |

| Smith | Smith | Smith |

Containment at The Point of Use

- Keep the unclean burs immersed in the cleaning / disinfecting agent in accordance with its manufacturer instructions, but in any event do not exceed 12 hours.

- Caution: Do not leave burs immersed in disinfectants.

Cleaning, Drying and Inspection Procedure

Manual Cleaning

- Rinse the burs under running cold water and, keeping them immersed, brush thoroughly away from the body using a neutral cleaning fluid

- After cleaning, inspect the burs, preferably with the aid of magnification, to ensure that all contamination has been removed. Repeat the cleaning process if necessary followed by autoclaving or boiling as per instructions given by the autoclave or boiler manufacturer.

- Dry the burs using dry heat not exceeding 140ºC.

Automated Cleaning

- Any cleansing and disinfecting agents used must be compatible with the materials used in the dental burs.

- The washer disinfector and the cleaning agent manufacturers' instructions must be followed.

- After cleaning, inspect the burs, preferably with the aid of magnification, to ensure that all contamination has been removed. Repeat the cleaning process if necessary.

In-Clinic Sterilisation

- Follow the autoclave manufacturer's instructions to sterilise the burs.

- Autoclave the burs for a minimum of 6 min at temperature of 134ºC.